Slurry walls are constructed using a cement-bentonite slurry to produce a below ground low permeability barrier.

Common uses

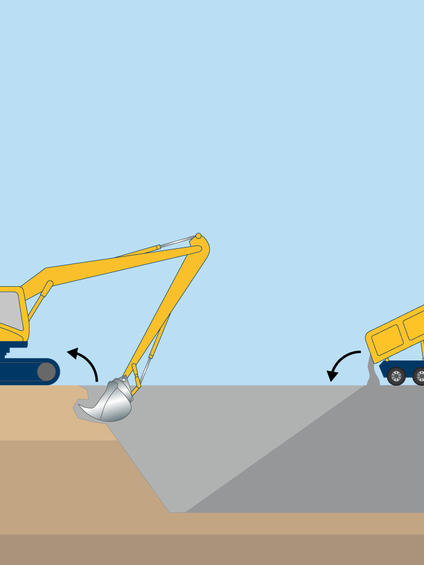

Process

A slurry cut-off wall or slurry trench wall is typically excavated using a backhoe (or grab) while simultaneously pumping a hydrated cement bentonite mix into the trench to depths in excess of 25m. Once cured, the slurry cut-off wall provides a permanent low permeability barrier to groundwater and leachates.

Where gas migration is the issue a high-density polyethylene membrane is placed in the wall in panels connected with an interlock system.

Specialist Contact | Anthony Lucas - [email protected] - +44 (0)7908 502122

Advantages

Quality assurance

Keller has decades of experience installing slurry walls across the globe.

A specially developed mix combined with strict quality control ensures consistency and a product installed and designed to withstand the test of time.

Samples from the top and bottom of the trench are taken daily and a series of testing can be done including slump, specific gravity, bleed, shear strength and pH.